MT-HF-TF no-clean halogen-free synthetic soldering tacky paste flux for MT alloys (REL0)

Ultra-low voiding halogen-free mid-temp Handcraft & SMD assembly

STIRRI®

SKU:TF-SMF-005-K

MT-HF-TF no-clean halogen-free synthetic soldering tacky paste flux for MT alloys (REL0)

MT-HF-TF no-clean halogen-free synthetic soldering tacky paste flux for MT alloys (REL0)

Couldn't load pickup availability

MT-HF-TF no-clean halogen-free synthetic soldering tacky paste flux for MT alloys (REL0)

- Resin-based synthetic low-activity REL0 (No-clean)

- World-class printability, instant activity response

- Halogen-free (EN14582). Passes BONO test.

- Ultra-Low voiding. Clear residue. Optimal viscosity. REACH-complaint flux

- Superior dispensing flow, smooth rolling, stellar stencil printing, excellent pin transfer.

- Sharp definition at high-speeds. Low solder balling and graping. Long stencil life

- Easy to clean using IPA, solvents, water-based saponifiers, vapor degreaser or ultrasonic devices

STIRRI®MtºHF-TF is a mid-temperature no-clean halogen-free synthetic REL0 soldering tacky paste flux for Tin/Lead (Sn/Pb) mid-temp assembly - Sn60Pb40, Sn62Pb36Ag2, Sn63Pb37 and similar mid-range leaded solder alloys.

Clear flux body and clear residue make MT-HF a good choice for hand-soldering

Contains QC-Aid™ optical tracer for instant visual contamination inspection. QC-Aid - Everyone can QC™

Wide application range

From hand-soldering electronics, automotive repairs, IC-chip replacement, BGA-reballing, gaming console repair to military/avionics-grade Tier halogen-free SMD solder paste.

Performance

Full body of enriched pine crystal rosins creating a transparent coating layer over the soldering area effectively blocking oxygen from the solder joints and thus allowing metals to bond - guaranteed!

Traits:

- Slightly yellow fully transparent rosin-rich flux body with clear non-corrosive residue. A truly no-clean flux - halogen-free, doesn't short components! REACH-compliant. Can be left on PCB or easily removed by hot air or basic solvents like Isopropanol.

- Used in MT solder paste and hand-soldering electronics/automotive repairs. Smooth dispensing and flow, excellent ability to hold components in place. Easy flowing under IC chips. Universal for leaded and lead-free alloys.

- Viscosity – 30-50 Pa/s (Malcom @ 10 RPM/25°C (x103Pa/s)) Halide-free (<0.05%). Passes BONO and SIR (Surface Insulation Resistance) test. No copper mirror breakthrough. Low electrochemical migration (<1 decade drop). 96°C-250°C temperature range.

- Offers spectacular low-voiding and truly no-clean performance in many professional soldering areas including SMD solder paste. Best performs with mid-temp range tin/lead alloys melting at 150ºC-200ºC.

- Contains QCAid™ - residual optical tracer glowing in UV blacklight allowing for immediate visual detection of contaminated PCB areas. QCAid - Everyone Can QC™

SMD-Paste values:

- Stencil life @ 30-70% RH - up to 16 hours - one of the longest values on the market allowing for a long process window and next day completion.

- Viscosity (jars, cartridges): 100-150 Pa/s (print-grade) and 80-100 Pa/s (Dispenser-grade), Tack force: 42-44g

- Stable wetting performance and low voiding soldering on most PCB finishes. Halogen-free clear residue. Sharp definition at high printing speeds up to 200mm/sec, enclosed print-head compatible.

Origin

Made in the USA using certified REACH-compliant raw materials, STIRRI specialty SMD-series have been helping the soldering community worldwide to reliably connect, clean and protect its craft. To see the difference, order your kit today!

Market

STIRRI®MT-HF compares to ALPHA® OM-6106 and Chipquik® SMD291; however, it features the QC-Aid™ optical tracer for instant visual contamination inspection, which is not offered by the market peers.

Product Description

Product Description

Suitability

Suitability

Designation

Designation

Viscosity

Viscosity

30-50 mPa/s (Malcom @ 10 RPM/25ºC (x 10³mPa/s))

Disclaimer

Disclaimer

The information contained herein is based on technical data that we believe to be reliable and is intended for use by persons having relevant skills at their own risk. Consumers should make their own tests to determine the suitability of each product for their particular process and take safety measures. Manufacturer/resellers assume no liability for results obtained or damages incurred through the application of the data presented.

Cleaning "No-Clean"

Cleaning "No-Clean"

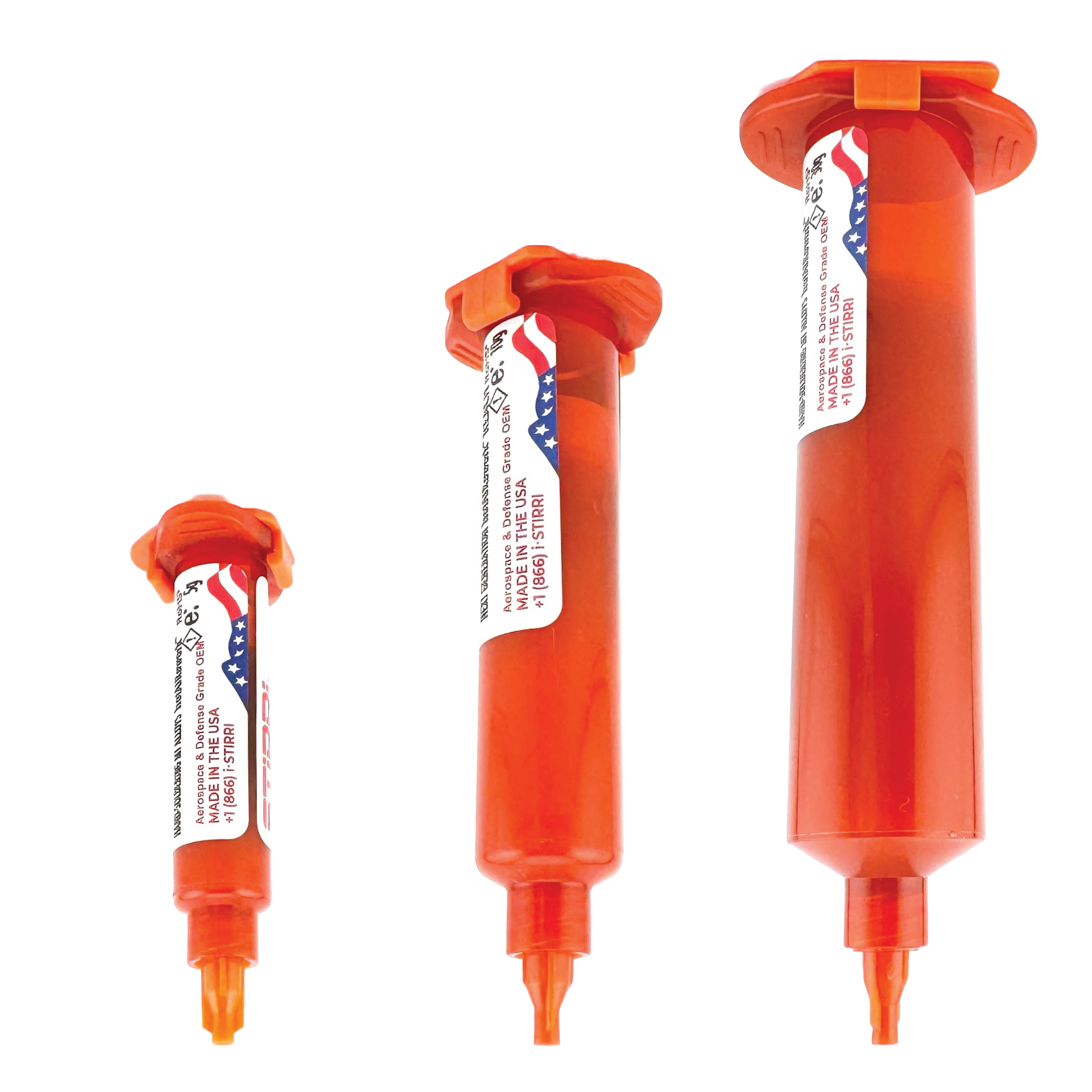

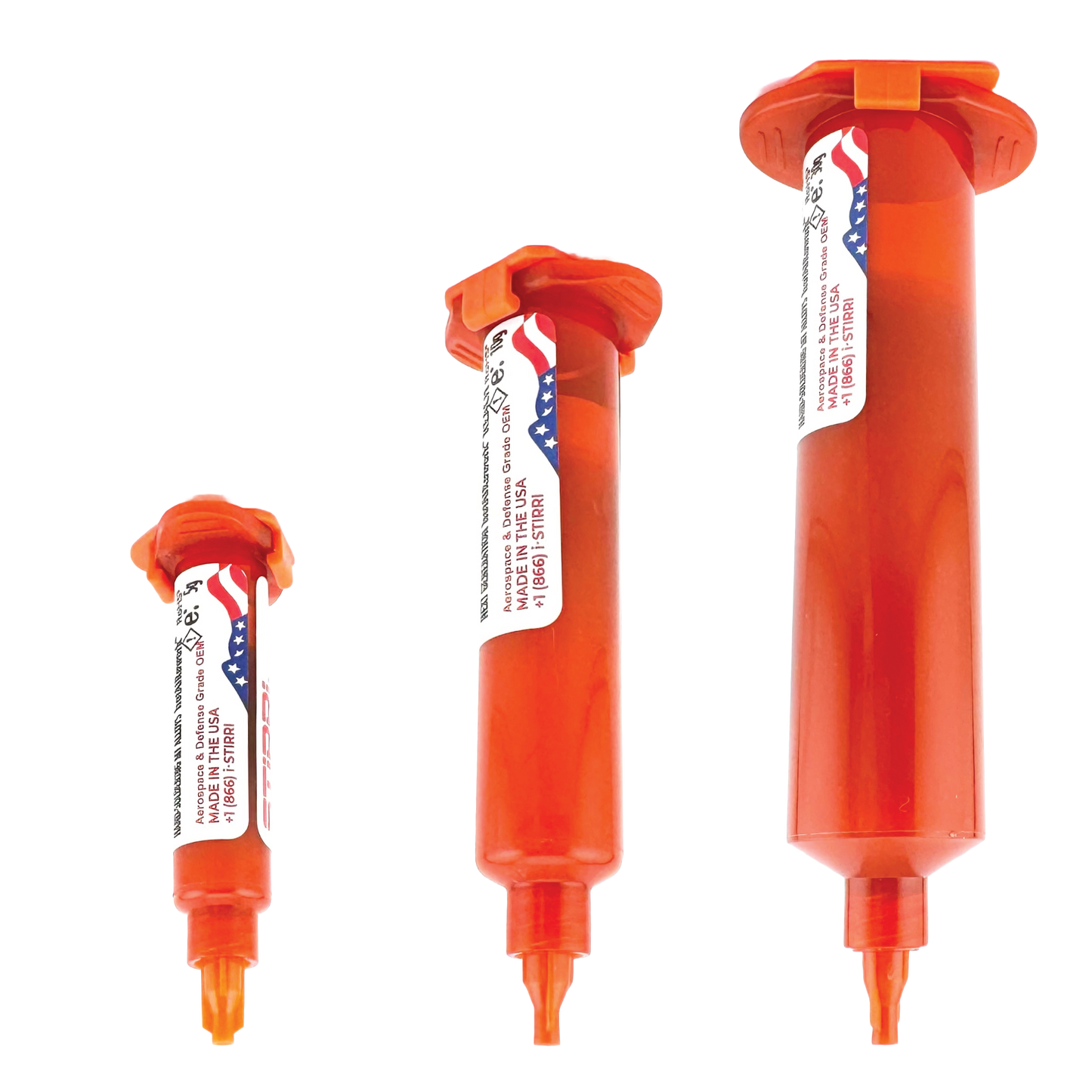

Dispensing Kit

Dispensing Kit

This product does not include any Dispensing Kit - a separate purchase!

Dispensing Kit is an add-on for manual dispensing, used to create a pressure with a plunger similarly to a medical syringe.

Air syringes intended for pneumatic dispensing machines use a piston stopper instead of a plunger. Do not remove the piston as it delivers the best seal preventing contact with air!

Compliance

Compliance

This material is certified REACH-compliant - does not use any raw materials from the REACH restricted list of substances of high concern.

Share

RFQ - Request For Quotation

You are in good hands!

Made in the USA to the applicable industry standards 100% customer satisfaction guaranteed!

Liquid-proof the assembly with Nano-Coating - dries in less than 8 seconds

STIRRI HydraCoat™ is a liquid repellent making PCB liquid proof, instantly improving assembly value!

With an impressive droplet contact angle of over 113º, this nonconducting solution creates an invisible hydrophobic shield repelling weather, humidity, moisture - coated PCB continues to function even when fully submerged!

Broadly suited for consumer devices, automotive circuits, urban and landscaping lightning, LED, medical or electronic devices, marine, boating and yachting industries.

Dry to touch in less than 8 seconds, self cures in 24 hrs or 10 min in 60ºC chamber.

STIRRI's Conformal nano-coating ensures end-customer satisfaction while virtually eliminating assembly claims due to environmental or consumer liquid damages.